Effective and efficient, reusing process water (a mixture of water and compound) and feeding it back into circulation during mass finishing can help you both save cost and protect the environment.

RECYCLING PROCESS WATER – FOR YOU AND THE ENVIRONMENT

Water and compound are essential for trowalizing. In most mass finishing applications, these valuable resources can be cleaned in centrifuges and fed back into circulation. This not only saves costs, but also protects the environment.

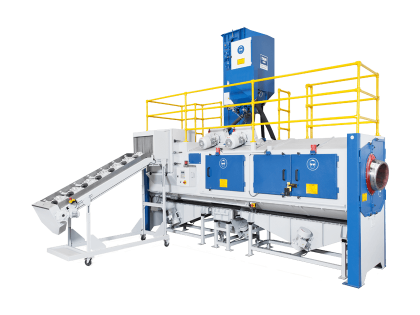

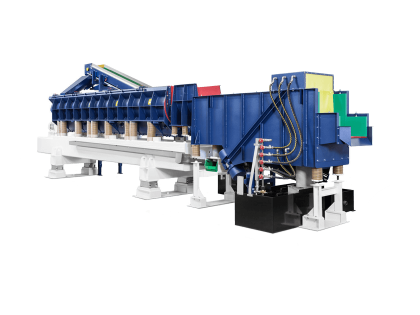

RELIABLE DISPOSAL OF PROCESS WATER

In some applications, it is not possible to recycle the process water, such as when pickling with acids or when using various compounds. In such cases, the water must be cleaned in a flocculant unit and then disposed of. We use two different water treatment systems- centrifugal and flocculant units. The main difference between the two is that water is being recycled in a centrifugal unit while in a flocculant unit, water is being treated and then disposed.

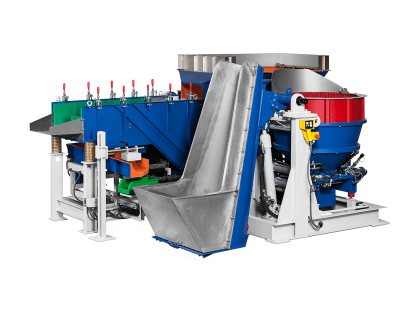

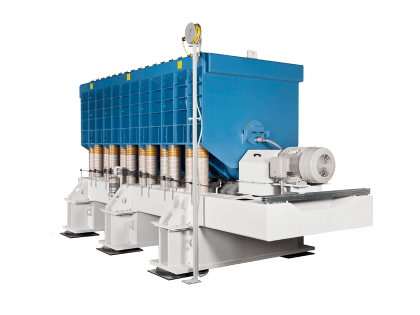

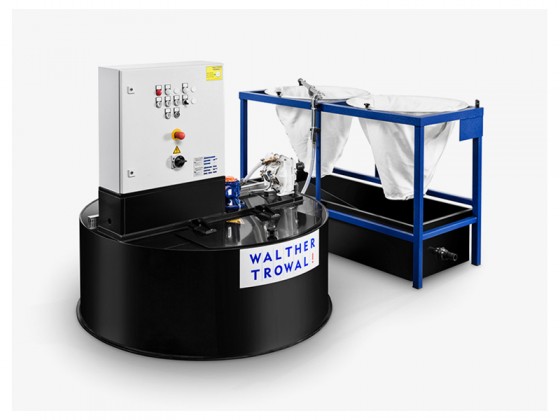

CENTRIFUGES

CLEANING AND RECYCLING THE PROCESS WATER

After mass finishing, the process water contains abraded material from the metal and abrasive media. Oil and dissolved metals are also often present. When cleaning in a centrifuge, the solid particles are removed from the contaminated water and separated as an airtight sludge. This results in a clean water/compound mixture that you can reuse for processing your workpieces. Alongside your centrifuge's annual maintenance as per accident prevention regulations, we also offer you a regular service in line with legal requirements. Centrifuges cannot be used everywhere. They are not suitable for the following mass finishing applications:

- Chemically accelerated procedures and paste processes

- Multi-stage processing with various compounds

- Pickling processes with acids

- Ball polishing applications