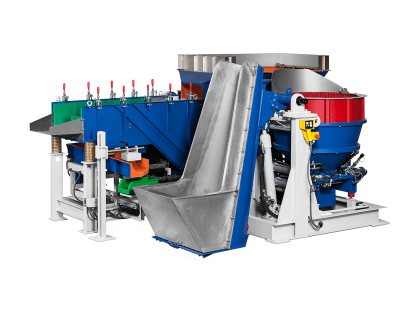

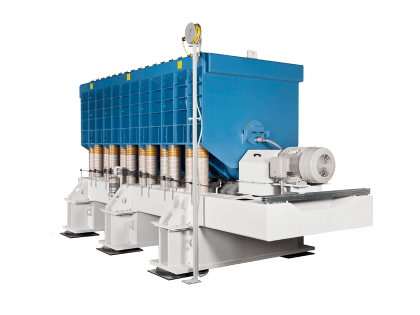

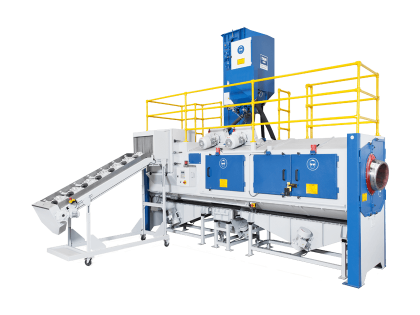

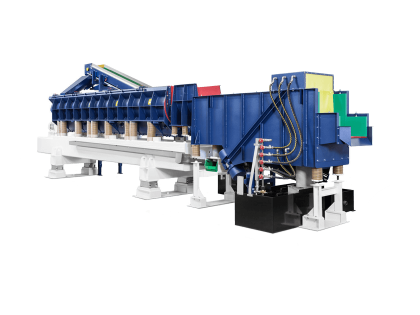

A VERSATILE SOLUTION

From deburring and rounding to high-gloss polishing, circular vibrators are universal mass finishing machines that can help to process a wide range of materials. You can use them to pre-grind work pieces or for producing surfaces ready for electroplating. Circular vibrators work extremely efficiently, making them suitable for use as both stand-alone unit or as part of automated production procedures. Ideal for small work pieces and industries dealing with precise, small to medium size parts.

We have different circular vibrators to cater to different needs of clients.