M-TMD

A HIGHLY EFFICIENT METHOD WITHOUT THE RISK OF WORK PIECES DAMAGING EACH OTHER

Compared to standard mass finishing systems, the newly developed M-TMD machine range finish high-value components 10 to 20 times more efficiently! By mounting the work pieces individually to workstations, which are part of a rotating carousel, you can process up to 18 work pieces in one single batch without risking part-on-part impingement. The different workstation angles (relative to their vertical position) also allow individual adaption of the machine parameters to your work pieces and guarantee absolutely stable finishing processes with excellent and repeatable results.

THE BENEFITS AT A GLANCE

- High-value, delicate work pieces

- Work pieces with many contours and complex shapes

- Extremely tough, difficult to machine materials

- Work pieces made from tungsten carbide and other hard metals

- Fan wheels for turbo chargers (automotive industry)

- Powered metal components, etc.

- Orthopedic implants (medical engineering)

- Turbine blades (for airplanes as well stationary turbines)

- Precision components, for example, for pumps and compressors

- Work pieces made from tungsten carbide and other hard metals

- Fan wheels for turbo chargers (automotive industry)

- Sintered components, etc

Technical Specifications

| M-TMD 4M | M-TMD 6M | |

|---|---|---|

| Dimensions (L x W x H) - with control panel | 1360 x 1610 x 2450 mm | 1680 x 2010 x 2620 mm |

| Machine Frame | ||

| -Robust welding construction | X | X |

| -Hydraulic aggregate for UP/DOWN movement of the work unit | X | X |

| Workbowl for wet application | ||

| -Work bowl lining with sprayed PU | X | X |

| -Top of bowl | ca. 840 mm | ca. 840 mm |

| -Depth of bowl | 440 mm | 440 mm |

| -Inner diameter | 840 mm | 1080 mm |

| -Vibratory motor for mixing | 1.35 KW | 1.35 KW |

| -Lifting station | X | X |

| -Volume | 240 litre | 430 litre |

| Dosing station for wet application | ||

| -Water and compound | X | X |

| Control panel | ||

| -Eaton touchscreen 10" for control of all functions | X | X |

| -Beacon light as optical alarm | X | X |

| Work Carousel | ||

| -Drive of carousel via gear motor | X | X |

| -Power | 4 KW | 7.5 KW |

| -Infinite RPM adjustment, variable from / to | 5 - 80 rpm | 5 - 80 rpm |

| -Sense of rotation: right / left run | X | X |

| Work stations | ||

| -Work stations with drive independent from the carousel | 4 pc | 6 pc |

| -Power | 3 KW | 3 KW |

| -Change of rotational direction, at choice left / right | X | X |

| -Infinite RPM adjustment from / to | 5 - 80 rpm | 5 - 80 rpm |

| -Supply of work piece fixtures | additional pricing | additional pricing |

| - Pitch point | 350 mm | 350 mm |

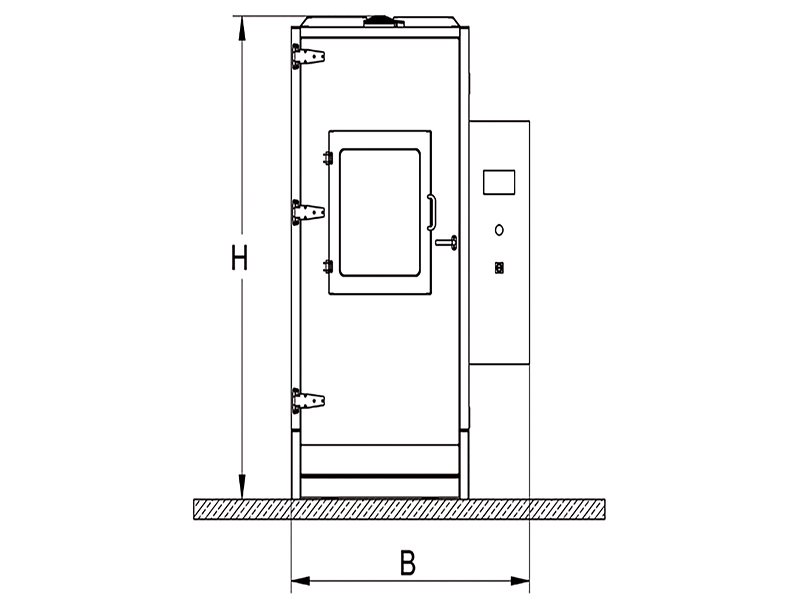

| Protective cabin | ||

| -Acc. to guideline 2006 / 42 / EG | X | X |

|

-Front door with manually activated operating window for change of parts fixture |

X | X |

| -Door and operating window locked electronically | X | X |

| Options | ||

| -Mono spindle with inclined position 0-25" in 5" steps | 0 | 0 |

|

-Triple spindle with inclined position 0-25" in 5" steps, transmission ratio 1 : 1.7 |

0 | 0 |

| -Work bowl for dry application | 0 | 0 |

| Technical changes reserved | ||

| X = standard | ||

| 0 = additonal pricing |