Rotamat for Small Parts Coating

COATING OF MASS PRODUCED, SMALL PARTS – ALSO FOR COMPLEX SURFACE GEOMETRIES

The Rotamat coaters are the economic solution for improving the surface of mass produced small parts by coatings made from elastomers, metal or wood – for example, O-rings, handles, springs or screws.

Even parts that have a complex shape or are extremely delicate are discharged from the machine with a perfect and complete dry coating. The coating process in the rotary drum is fully automatic. The cost-intensive and time-consuming placing of the parts on special racks, which are required in conventional coating systems, is no longer necessary.

THE PRINCIPLE behind the coating process

The work pieces gently tumbling over each other in the rotating drum. This results in an intensive mixing effect which evenly exposes the work pieces to the spay pattern of the spray gun at different angles – a pre-condition for an even coating thickness. The special drum shape and the adjustable rotary speed ensure an optimum tumbling and mixing of the work pieces. The drum inclination is infinitely adjustable within a certain angle and can, thus, be precisely adjusted to different work piece shapes.

The ideal angle of inclination for the various coating processes is determined by the free processing trials for your individual application. Different drum sizes for different part volumes are available. Exchanging one drum with another is easy and requires very little downtime. This allows the Rotamat to adapt quickly to different batch sizes or coating processes. If required, the inside of the drums can be lined with a 3S-coating. In addition, the inside of the cover and the drum housing can be coated with an anti-adhesive material. Once the coating process is completed, the drum is mechanically tilted downward to gently discharge the finished work pieces, which are now ready for the next production step.

HOMOGENEOUS APPLICATION OF THE COATING MATERIAL

An automatic spraying systems evenly applies the coating material onto the work pieces that are gently tumbling in the rotating drum. If requested, the machines can be equipped with two spraying systems. This is usually for cases whereby the work pieces have to be coated sequentially with two different materials like base and topcoat or primer and cover.

The type HVLP automatic spraying systems used in the Rotamat coaters produce very little spray mist resulting in a minimum of overspray. A window in the drum cover allows the operator to visually inspect the coating process. The inside of the drum is equipped with explosion-protected LED lights.

OPTIMUM TEMPERATURE

During the coating process, pre-heated filtered air is injected into the rotating drum to heat the work pieces to a pre-set temperature, which is precisely adapted to different work piece types and materials as well as different coating materials. Throughout the process the work piece temperature is monitored by an IR sensor, and the inlet air temperature is adjusted as required. This results in a highly homogeneous and evenly coated surface which creates an intensive bond between the coating material and the work piece surface. The coating material already dries during the actual spraying process. Post process drying in a separate oven is no longer required.

REPEATABLE COATING RESULTS

An industrial PC monitors and controls the entire process. The integrated recipe administration stores all process parameters created for the different applications and allows quick access to the different recipes. These include work piece quantities, inlet air temperature, drum speed (RPM), spraying volume and spraying pattern of the automatic spraying system, to name a few. The result: A stable and repeatable process with absolutely perfect coating The intuitive process visualization, simple operation of the touch panel and process and control functions makes it very easy to work with the Rotamat

ECO-FRIENDLY OPERATION

Each Rotamat coater is equipped with a 4-stage exhaust air filter system including a Papp labyrinth filter, a filter mat and pocket filters. The rotating drum is sealed allowing the work pieces to be processed under a slight negative pressure. This prevents noxious volatile materials from escaping into the environment.

THE BENEFITS AT A GLANCE

- Good for even complex shapes

- Fully automatic and uniformed coating

- Homogenous applications

- Different drum size for different part size available

- Optimal temperature adjustable

- Post process drying in an oven no longer required

HOMOGENOUS PROCESSDecorative coatings - Improves the part surfaces with a wide range of decorative and functional coating materials, eco-friendly, solvent-free lacquers and single- or two-component special lacquers. Lubricating coatings - Reduces the coefficient of friction and prevents chatter and stick/slip effects on small parts like O-rings, sealing components or valve stems. It also facilitates the problem-free separation of the work pieces. Application of a bonding agent - Single or double layer systems consisting of primer and cover create a strong bond between the substrate and the elastomer. Coating for corrosion protection - Creates a long lasting protective layer without the use of hazardous chemicals. For example, compared to dip/spin coating the drives of small and micro screws remain open providing the required optimum grip. Coating for insulation purposes - Special coating materials provide an insulating layer for electronic components like ferrite cores and rings or capacitor sleeves. |

Rotamat R60

| R60 | R80 | R90 | |

|---|---|---|---|

| Power (kVA) | 19 | 16 | 16 |

| Power Supply (V/Hz) | 400/50 | 400/50 | 400/50 |

| Compressed air, dry, oil-free (in bar) | 6 | 6 | 6 |

| Drums | |||

| Drum (mm) | 400/550/600 | 400/550/700/800 | 400/550/700/800/850 |

|

Filling weight max. (kg) / Filling volume max. (l) |

25/15 | 60/50 | 100/75 |

| Speed of drum (rpm) | 2....30 | 2....30 | 2....30 |

| Inlet air system | |||

| Transporting capacity max (m³/h) | <160 | <160 | <160 |

| Heating capacity (kw) | 9 | 9 | 9 |

| Increase of temperature max. (K) | 130 | 130 | 130 |

| Exhaust air system | |||

| Transporting capacity max (m³/h) | <200 | <200 | <200 |

| Filtration | 4 stage (paper, G2, G4, F6-cx) | 4 stage F6 | 4 stage F6 |

| EX marking (as per type plate) | Ex II 1G/3G bc IIB T3 X/- | Ex II 1G/3G bc IIB T3 X/- | Ex II 1G/3G bc IIB T3 X/- |

| Max infeed of solvent (g/h) | 1000 | 1000 | 1000 |

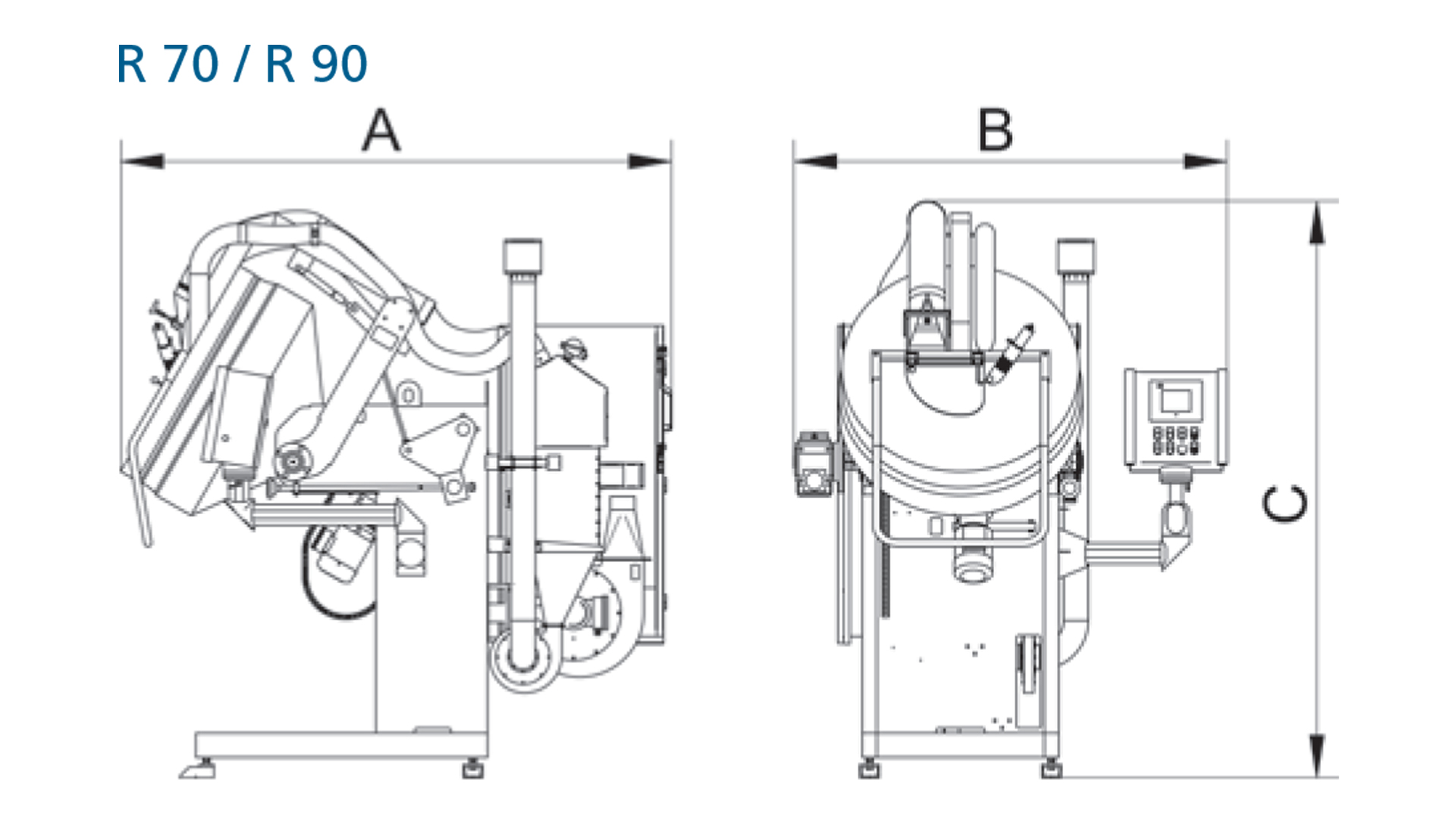

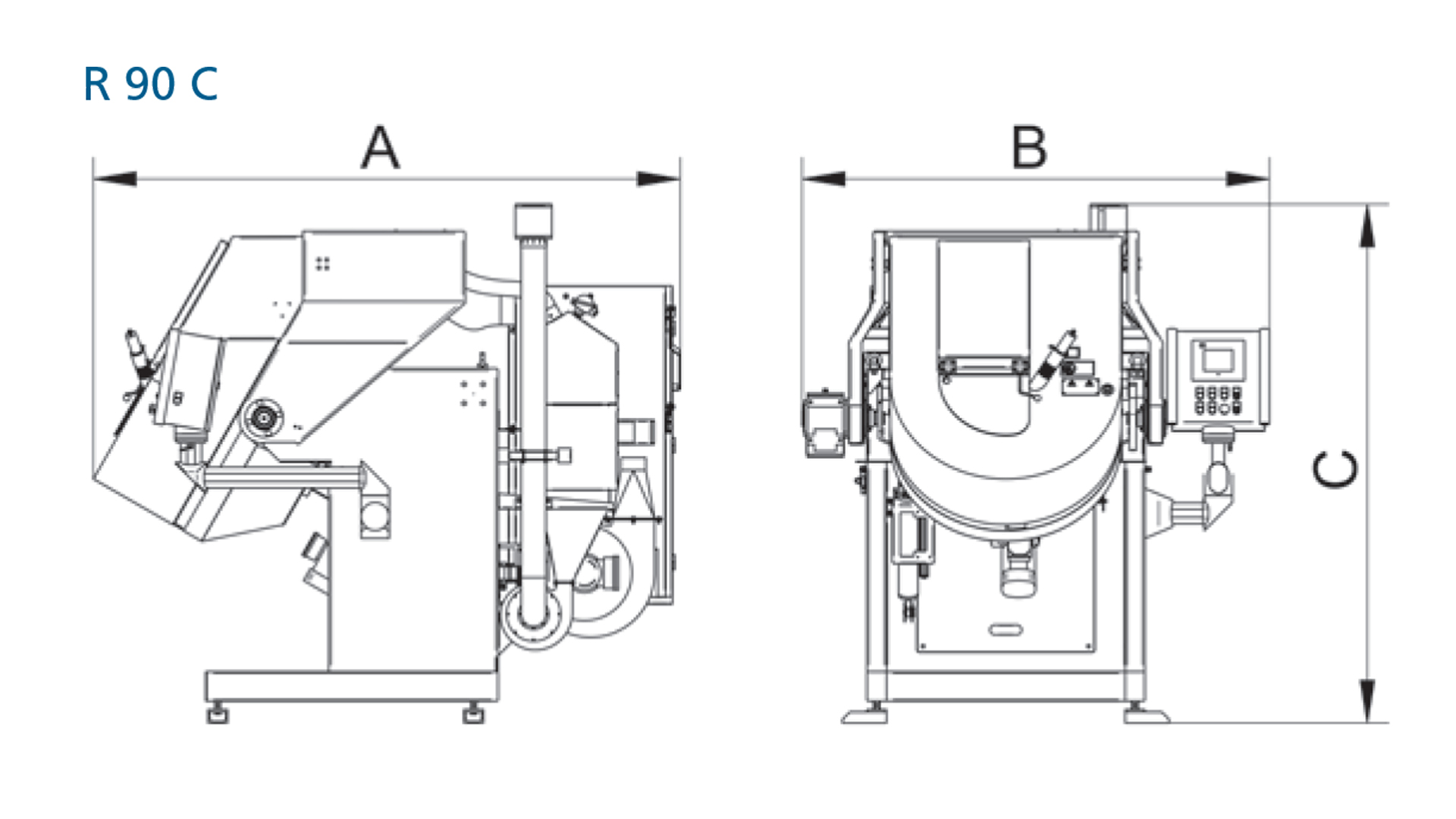

| A (depth) | 2080 | 2140 | 2410 |

| B (width) | 1250 | 1920 | 1920 |

| C (height) | 2010 | 2340 | 2130 |

| dimensions in mm |